Savings on energy and better quality air starts with your air compressor.

When using air compressors there are many ways to save on energy. Installing VFDs, lowering the pressure, and turning off the compressor at night will increase your energy efficiency but that savings is only a drop in the bucket compared to the cost of running an air compressor. The cost of using an air compressor can be in the thousands of dollars and if you are using a dryer that cost can double in size.

COMPRESSED AIR COSTS BREAKDOWN

Using springs and timers isn't proven.

Active feedback changed everything.

Why should you become an expert at figuring out your air compressors programming? The active feedback based Compressor Controller does that automatically. Using the active warm start technology lowers the stress and energy use during pump starts. Then monitoring for overheating and ruptures while in use and draining the tank automatically for a 100% reduction in moisture content in the tank. The active feedback in the Compressor Controller optimizes air compressors in Real-Time, by constantly evaluating environmental and operational conditions and adjusts compressor operation to continuous peak performance, self-adjusting in real-time.

Active Warm Start

All Digital

Smart Drain

Compressor City

Compressor Controllers saves on energy

& increase air quality. Here’s the proof:

A Department of Energy-funded Product Performance Study carried out by engineers at Pecan Street in 2019 demonstrated that the compressor Controller is able to deliver startup energy savings of 23% and a compressed air moisture reduction by 100%. Why is this significant?

100% Moisture Reduction in compressed air may mean that air drying can be reduced or eliminated altogether.

23% Startup Energy Savings means that everytime the compressor starts it uses less power and puts a lower strain and wear on the compressor.

Moisture Reduction

Energy Savings

whos already using the Compressor Controller?

What Clients Say?

The Compressor Controller worked exactly as it should have when the pressure sensor broke. I came in the next day and the pump was off and alarm was on. It saved my pump from running all night.

The more I use your product, the more I like it & I really didn’t know I had such a need in the first place… [..] a business running several tools at once, this is a must in order to keep a compressor running like new.

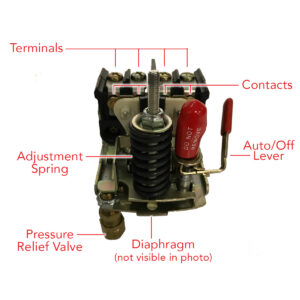

Meet the Compressor Controller

The Compressor Controller Retrofits Air Compressors with Full Automation that Saves Money and Reduces Downtime. It is simple to install and easy to use.

Designed for electric single and duplex pump reciprocating air compressors. It’s a true manager-in-a-box controller system that optimizes performance, reports conditions, and delivers savings every time you use it making it a purchase that pays for itself year after year.