Air Compressor energy Efficency and better Air quality Just Got Easy!

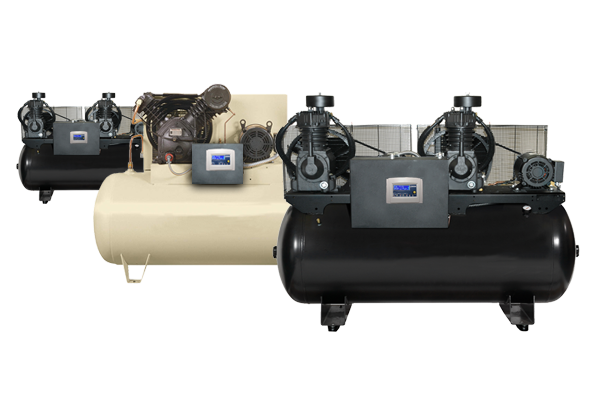

Introducing the Compressor Controller: unlock immediate savings and stabilize the performance of the air compressor and the tools it powers. By automatically optimizing the compressor the Compressor Controller typically pays for itself within the first year, making it a valuable asset to streamline compressed air system and reduce costs.

What does an average 7.5-HP air compressor really cost?

Why the Compressor Controller for a Dual Pump 7.5 HP compressor in numbers

Where is the waste?

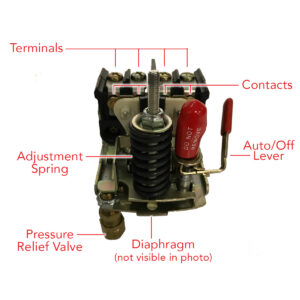

For years, air compressors have relied on traditional components like pressure switches with springs, timer-based controls, and standalone air dryers. While these tried and true methods have been around for a long time, they come with hidden costs that can significantly impact the bottom line.

Springs Drift

timers Just Dont know

Overworked Air Dryers

Air dryers, responsible for removing moisture, frequently operate beyond their required capacity, inadvertently increasing the energy consumption of an air compressor system. (The Compressor Controller, in certain situations, may even render a separate dryer obsolete, thereby further diminishing equipment and operational costs.)

Active feedback changed everything.

The active feedback-based Compressor Controller automatically optimizes air compressor operation, maintaining peak performance, maximum efficiency, and enhanced safety. By constantly evaluating environmental and operational conditions, the Controller eliminates the need for manual daily programming. User preferences can be modified, but the default settings ensure optimal performance without extensive training. Investing in a Compressor Controller with active feedback programming streamlines air compressor management, allowing you to focus on other critical aspects of your business while achieving maximum operational efficiency and safety.

Operational Benefits

Active Warm Start

compressor pump unloading during startup, reducing peak power draw, reducing pump-oil water contamination and extending the life of critical components.

All Digital

Smart Drain

sCALE iNSTANTLY

Added Safety

Overheat and Overrun Safeguards

Rupture Detection and Prevention

Compressor Controllers saves on energy

& increase air quality. Here’s the proof:

A Department of Energy-funded performance study by Pecan Street Labs validated three key improvements that directly impact your compressed air system’s efficiency and reliability: Why is this significant?

100% Moisture Reduction: Testing showed moisture accumulation dropped from 5.5 oz to near zero per cycle, effectively eliminating the need for separate air drying equipment or draining.

23% Energy Savings: Documented through rigorous measurement protocols combining:

- Eliminated energy waste from tank draining cycles

- Optimized pressure control

- Reduced inrush current and startup load

Why This Matters: These independently verified improvements translate to immediate cost savings through reduced energy consumption, eliminated moisture-related issues, and extended equipment life – while providing precise digital control over your compressed air system.

Moisture Reduction

Energy Reduction

Enhanced System Performance:

- Pressure stability

- Inrush current reduced

- Validated thermal protection and safety features

- Automated moisture management and system monitoring

who is already using the Compressor Controller?

What Clients Say?

The Compressor Controller worked exactly as it should have when the pressure sensor broke. I came in the next day and the pump was off and alarm was on. It saved my pump from running all night.

The more I use your product, the more I like it & I really didn’t know I had such a need in the first place… [..] a business running several tools at once, this is a must in order to keep a compressor running like new.

Meet the Compressor Controller

The Compressor Controller: All-in-One Cost Savings and Performance Optimization

Retrofit your air compressors with the user-friendly, easy-to-install Compressor Controller for full automation, reduced downtime, and substantial savings. This manager-in-a-box solution optimizes performance, reports conditions, and delivers savings with every use, making it an investment that pays for itself year after year.