Compressor Controller

For Single and Duplex Reciprocating air compressors

Model R100 & R200

What is the Compressor Controller

The Compressor Controller is a proven controller designed to automatically manage single, duplex, or multiple reciprocating air compressors together. By optimizing compressor operation, this system provides improved efficiency, reliability, and safety. Discover the advantages of digital air compressor automation and management with the Compressor Controller.

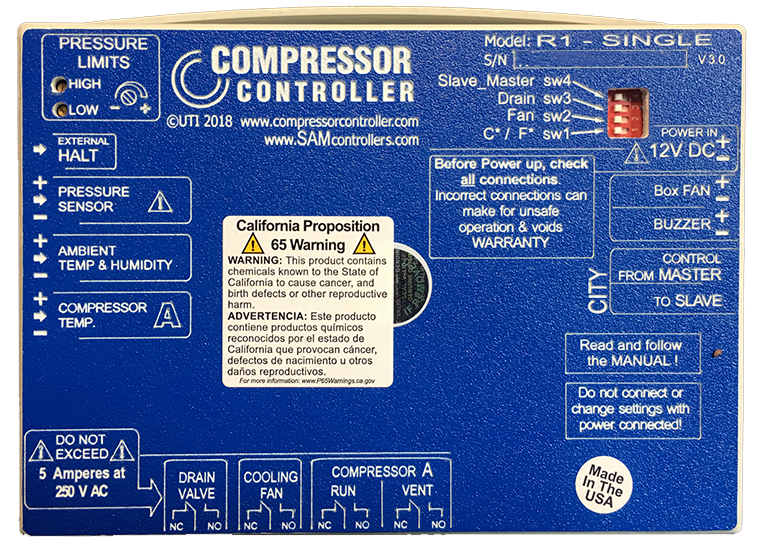

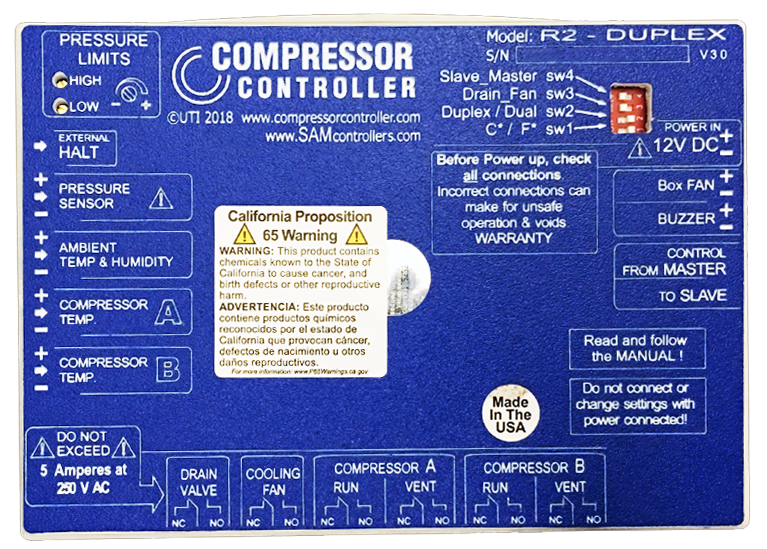

Front

Model R100 – designed for single pump/motor reciprocating air compressors

Model R200 – designed for two pumps / motor reciprocating air compressors

Display – operated with just one button.

- current and set pressure (psi)

- pump hour & cycle counter

- minimum/maximum operating temperatures

LED Status indicators – pump, active warm start, fan, drainage, and compressor city operation.

Back

Pressure Limits – Digital settings for high and low pressure limits, allowing precise control over the compressor’s operating range.

External Halt – When this connection is closed, the compressor stops, enabling integration with other systems or automation.

Pressure Sensor Input – Three-wire connection to a high-accuracy digital pressure sensor for real-time monitoring of system pressure. (included in kit)

Ambient Temperature & Humidity Sensor – Sensor for measuring the temperature and humidity of the air being compressed, ensuring optimal performance. (sensor included in kit)

Compressor Pump Temperature Sensor – Measures the pump temperature, providing valuable data for maintenance and troubleshooting. (included in kit)

Drain Valve – Connects to a powered solenoid drain valve for efficient removal of condensate from the system.

Cooling Fan – Connects to an optional intercooler fan, improving heat dissipation and system efficiency further.

Box Fan Connection – Allows the connection of an optional panel fan, useful in panels with solid state starters and VFDs.

Compressor City Connection – Connection to another compressor controller, allowing the addition of instant capacity or redundancy.

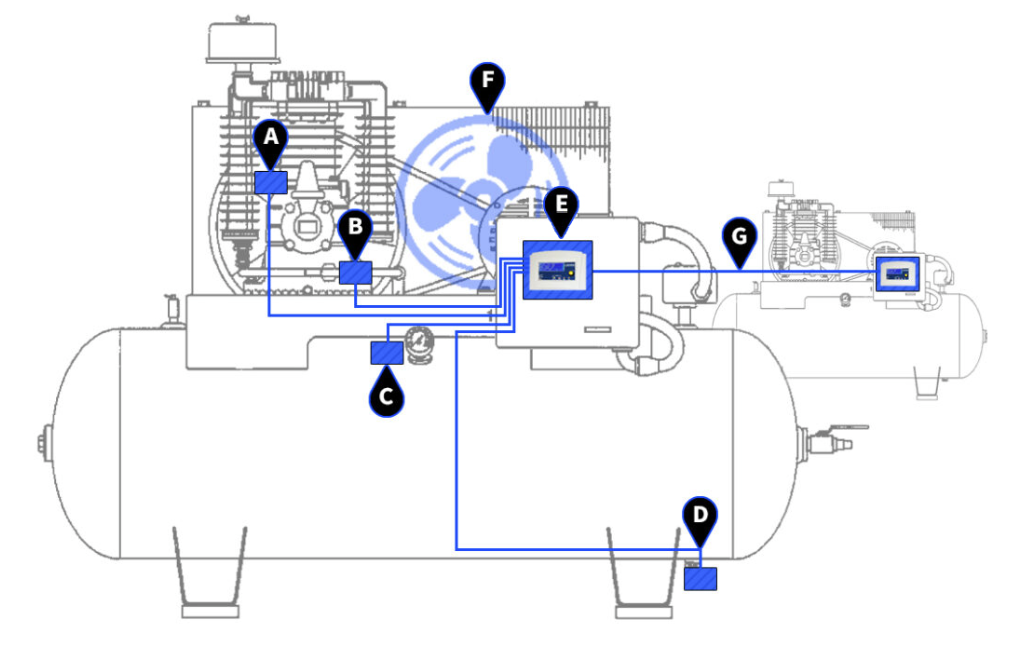

How the Compressor Controller Connects

The Compressor Controller is designed to seamlessly connect as an add-on to any single or dual pump reciprocating compressor, making it a versatile and easy-to-install solution for enhancing the performance and efficiency of your existing or new air compressor system.

Installation Overview

Typically takes 2-3 hours

Requires 10 minutes of initial configuration

Can be combined with a VFD or Solid State starter for even greater efficiency.

DIY Installation

Easy to follow instructions

Specific model kits that are bolt on ready

Utility Rebates Eligible

The Compressor Controller is simple-to-install, bolt-on automation:

Reciprocating air compressors

Single and multiple pump systems

Any number of stages

Seamless integration with or without a dryer, often eliminating the need for one

Integration Diagram

A. Pump Temperature Sensor – Measures the pump temperature and performance.

B. Unloader Valve – an electrically (NO) actuated valve that is added to the existing unloader valve.

C. Digital Pressure Sensor – 304 Stainless steel, digital pressure sensor with 1% accuracy and long-term stability.

D. Drain Valve – an electrically (NC) actuated valve that is added to the drain valve and automatically controlled.

E. Compressor Controller – installed in to an enclosure.

F. Intercooler Fan Output – NO and NC output for an auxiliary fan, an and can be optionally installed to improve intercooler performance in two-stage air compressors.

G. Compressor-City link – Connection to other Compressor Controllers to scale air compressors for higher CFM and/or increased redundancy.

Benefits of the Compressor Controller

The Compressor Controller is a game-changing solution that optimizes the performance of reciprocating air compressors, delivering substantial energy savings, reducing maintenance costs, and eliminating the need for expensive air drying equipment. With its advanced features and intelligent control, this all-in-one system provides:

Operational Benefits

Active Warm Start Intelligently manages compressor pump unloading during startup, reducing peak power draw, reducing pump-oil water contamination and extending the life of critical components.

All Digital Drift-free digital pressure sensor and precise tracking of operational metrics (hours run, maintenance timer, and issues) ensuring optimal performance.

Smart Drain Automatically calculates and drains moisture from the tank, achieving 100% air moisture reduction without wasting pressure or causing clogs.

Scale Instantly Effortlessly add additional compressors to an air network with pairing two Compressor Controllers together to increase capacity and/or redundancy.

Added Safety

Overheat and Overrun Safeguards The Compressor Controller continuously monitors pump temperature and runtime, detecting when critical thresholds are reached. This advanced protection detects and prevents additional damage from overheating or excessive wear, ensuring the longevity of your equipment.

Rupture Detection and Prevention The controller identifies sudden ruptures in air networks and prevents the compressor from starting, shielding air systems from costly damage and minimizing downtime. This proactive approach safeguards your investment and keeps operations running smoothly.

How to Get Started Compressor Controller

Take the first step towards optimizing your compressed air system by working with a local installer or purchasing the Compressor Controller and necessary components today.