Unloader valves are essential components in air compressors, releasing pressure before and after compression. They ensure a pressure-free start, release remaining air upon stopping, and come in various types including mechanical and electrical. These valves are typically located between the compressor and tank, often integrated into the pressure switch or pump axis. Their operation is crucial for efficient compressor function and longevity.

The Compressor Controller’s Role

Modern compressor controllers, like the Model R, enhance the function of unloader valves:

- At Start: The controller keeps the valve open until the pump reaches optimal temperature (1-40 seconds : based on feedback on pump temperature and current operating conditions).

- At Stop: The controller opens the valve to drain and unload the pump after reaching the cut-out pressure.

This intelligent control offers several benefits:

- Reduced peak current at startup

- Less oil-water contamination

- Decreased condensate in the storage tank

- Extended compressor lifespan

Selecting an Unloader Valve

When installing a compressor controller:

- Choose an electric (Typically a NO – Normaly Open) solenoid valve matching your compressor’s voltage and pressure specifications.

- Install and connect it to the Compressor Controller

- Original valves remain in place, with the electronic valve added alongside.

The unloader valve plug should have an orifice allowing a 5-second air purge after operation.

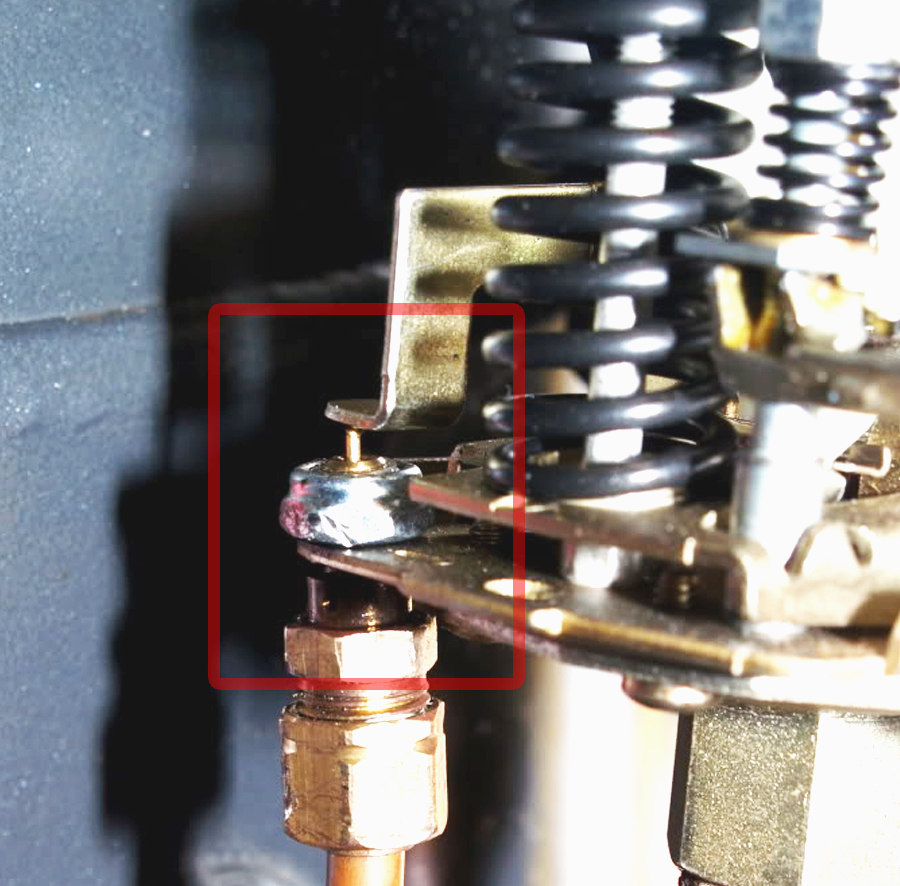

Unloader Valve Example

Installation Example:

For a 5HP single-phase compressor (single or dual pump):

- Tank size: 80-gallon

- Operating pressure: 120 PSI

- Unloader Valve: 110VAC NO (Normally Open) 1/8 NPT electric solenoid

- Unloader Valve Plug: 1/16″ drilled orifice for 5-second air purge

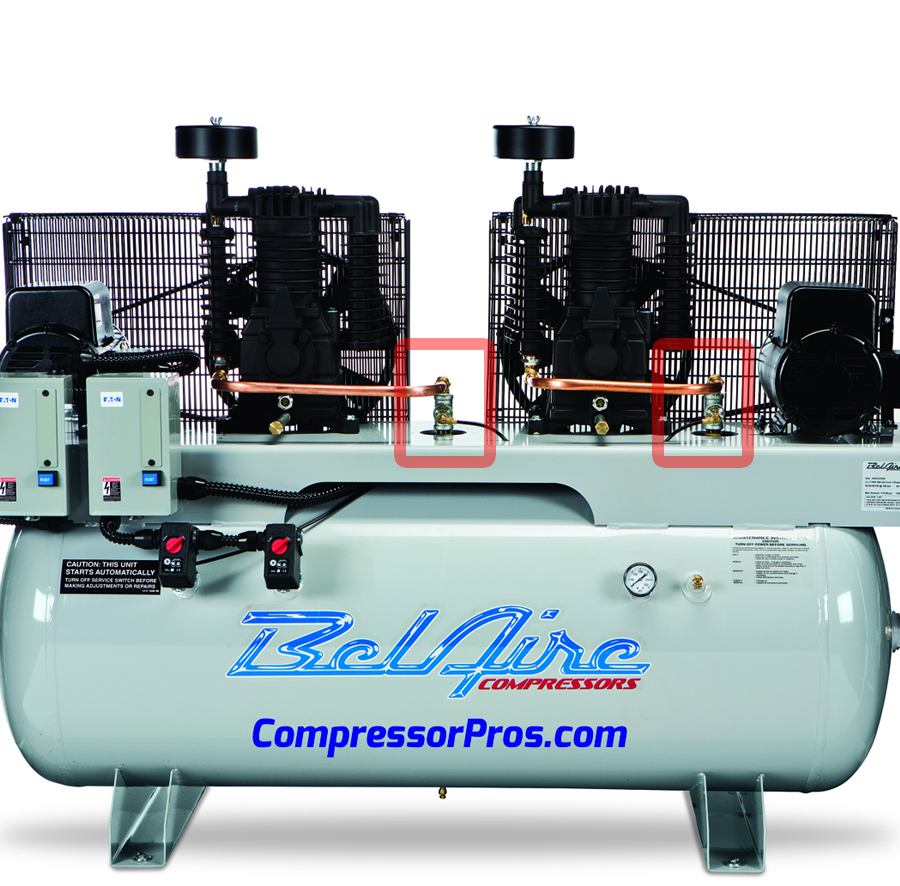

Note: Dual pump systems require an electric unloader valve for each pump.

Proper selection and maintenance of unloader valves are crucial for efficient, long-lasting compressor operation. Consult with a professional for your specific system needs.

Buying a Complete Kit:

For those looking to upgrade their air compressor system, purchasing a complete unloader valve kit can be an excellent option. These kits typically include all necessary components, such as the unloader valve, valve plug, fittings and enclosure. By choosing a kit, you ensure compatibility between parts and simplify the purchasing process. Kits often come with detailed instructions, making them suitable for faster and more assured integration of the Compressor Controller. However, it’s crucial to select a kit that matches your specific compressor model and requirements. See our available kits

Professional Installation:

While installing an unloader valve can be a DIY project for some, many compressor owners opt for professional installation. This approach offers several advantages. Professional installers bring expertise and experience, ensuring that the unloader valve is correctly integrated into your existing system. They can also identify and address any other issues with your compressor during the installation process. Professional installation often comes with warranties or guarantees, providing peace of mind. Additionally, for complex systems or in situations where safety is a concern, professional installation is highly recommended. Although it may cost more upfront, the long-term benefits of proper installation, optimal performance, and reduced risk of errors can make it a worthwhile investment. Find an installer in our network